Cold Spray Anti-fouling treatment for seismic equipment

Every year Seismic operators spend and lose millions of dollars managing barnacle infestation of streamers and attached components. The cost to the industry is not just financial, there are significant HSE risks associated with current methods of managing this problem.

Typical Barnacle Infestation

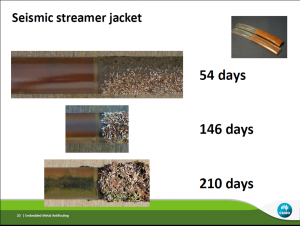

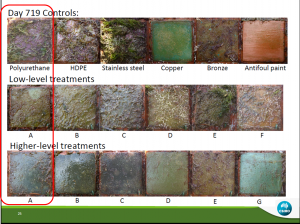

Current solutions are basically reactive and boil down to various devices and methods for mechanically removing barnacles after the infestation has occurred, while still exposing operators to significant HSE risk. Until recently, no viable preventative technology has been available until the Australian CSIRO developed a technology for treating polymer surfaces with a common anti-fouling agent using the cold spray process. Harbour tests have been conducted in Australia with very encouraging results. See below.

Harbour Tests – Streamer Jacket – Tropical Queeensland Harbour (Click to open)

Harbour Tests – Various Materials – Victorian Harbour (Click to Open)

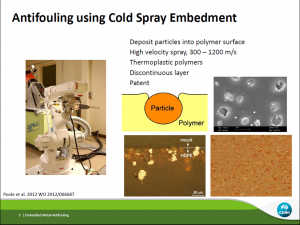

Cold Spray Particle Embedment

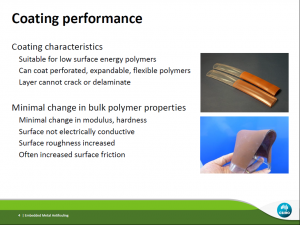

What differentiates cold spray from previous technologies is that it is not a coating, the active material is embedded in the surface of the item being treated. The penetration depth is in the order of 0.1mm so there is no change to the bulk properties of the substrate material. The treatment does not wear off because it is embedded and cannot peel or flake off because there is no interface between the treatment and the substrate along which a crack could propagate as would be present in a traditional coating system.

Useful Links

Cold Spray Antifouling of Marine Seismic Streamers

Technical Paper – Embedment of Copper Particles into Polymers by Cold Spray

Cold Spray Anti Fouling of Polymer Surfaces

Embedment (Click to open)

Coating Performance (Click to Open)

Phoenix Engineering

Phoenix have secured a 10 year exclusive license for the use of this technology in seismic streamer applications and we are in the process of developing equipment that can apply the process to seismic streamers in an efficient and economic fashion. Please contact us if you would like to know more about he technology. We will be happy to provide samples that can be used for your own in water testing.

The cold spray anti fouling technology can be packaged in various ways. For example it could be designed as a permanent installation in a jacket or streamer manufacturing line. A more likely application would be as a mobile unit designed to be used to treat streamers in the existing pool. The picture on the right shows a containerised design based on a standard 20 foot container. The unit is designed to process an 8 Km streamer in 24 hours and could be positioned in any location convenient for access to the streamers such as a dockside, yard or warehouse.

Another possible application would be as a permanent installation on a large multi-streamer vessel.